Power Electronics—Key Technologies for Sustainable Energy Applications

Discover the focus topic “Power Electronics.” It’s all about semiconductors, energy conversion with minimal loss, and our path toward a decarbonized and digital society.

The Focus Topic: Power Electronics

Explore the fascinating world of power electronics—and how it contributes to driving the energy transition. With cutting-edge semiconductor technologies, it’s revolutionizing both our power grids and how we generate, store, and consume energy.

What does Power Electronics mean for innovation?

Power electronics play a central role wherever electrical energy must be controlled, converted, or distributed. Its significance grows alongside global demands for energy efficiency, sustainability, and digitalization. Applications include:

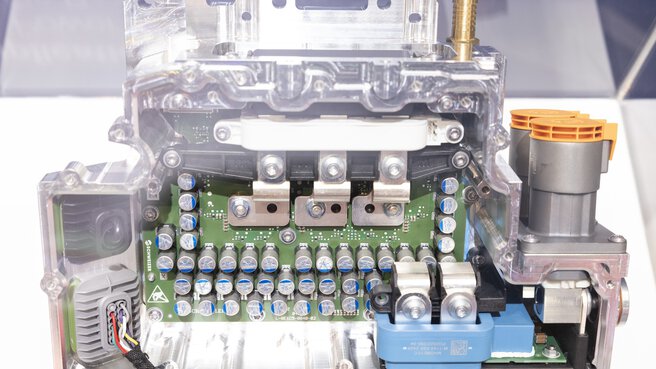

- Automotive Components

SiC- and GaN-based components extend electric vehicle range and enable faster charging. Integrating power electronics into the drivetrain results in more compact and efficient propulsion systems.

- Smart Energy & Building Automation

For maximum comfort with energy efficiency: From lighting controls and HVAC systems to solar charging and inverter units, the focus is on compact, durable, and high-efficiency modules. DC power supply is becoming more common in buildings.

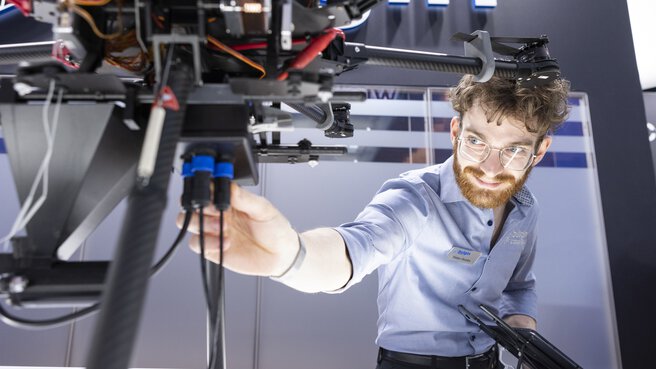

- Industrial Electronics

Power modules used in harsh environments require high quality standards, reliability, and protection methods such as potting or coating. Power electronics enable direct use of solar or wind energy in production processes.

- Energy Storage Systems & Charging Electronics

Battery management systems, DC/DC converters for energy storage, and onboard chargers require materials with exceptional properties like AlN ceramics or low-loss magnetic materials.

Why is Power Electronics especially important right now?

- Energy Transition:

Power electronics enable the transformation of energy generation and transmission structures – crucial for achieving energy transition goals. - Energy Efficiency:

Power semiconductors optimize energy use during conversion, significantly increasing efficiency and reducing global energy consumption. - Decarbonization:

Power electronics technologies support decarbonization and reduce CO₂ emissions. - Digitalization:

The development of smart Power ICs allows for high integration density, driving digitalization in many applications. - Material Innovations:

Wide-bandgap materials like silicon carbide (SiC) and gallium nitride (GaN) open up new possibilities for high-performance, efficient electronic systems. - AI Applications:

Rising demands in AI infrastructure require powerful platforms built on cutting-edge power electronics. - Future Technologies:

Research into new materials such as gallium oxide (Ga₂O₃) and diamond, advanced packaging technologies, and new circuit topologies promise further breakthroughs in power electronics.

What Are the Challenges in Power Electronics?

- Thermal Instability:

Risk of malfunction and failure due to overheating in applications involving high currents and voltages. Especially in compact designs with high power densities, efficient thermal management is critical. - Cost-Benefit Analysis:

Weighing the cost versus efficiency benefits of SiC MOSFETs and Si IGBTs, particularly given significant price differences. - Complex Design:

Especially relevant when using SiC MOSFETs to optimize thermal performance and reduce cabling requirements – but this increases demands on packaging and system design. - Application Suitability:

Selecting the right technology for a given application is complex. Design teams have to conduct thorough, systematic evaluations. - Effective Integration:

Combining SiC MOSFETs and GaN HEMTs (e.g., in electric vehicles) can improve system efficiency but requires advanced design expertise and careful coordination of all components.

The Trade Fair Program on the Focus Topic of Power Electronics

The driving forces behind the power electronics industry are also highlighted in productronica’s high-caliber supporting program. Knowledge transfer and professional exchange are at the heart of the event.

Which companies will present their solutions and products related to power electronics?

At productronica 2025, numerous companies will showcase their latest innovations in the field of power electronics:

- Semiconductor and chip manufacturers:

Developers and producers of advanced semiconductors and chips - Cooling technology developers:

Manufacturers specializing in heat dissipation and thermal management solutions - Manufacturing technologists:

Providers of machinery and technology for production and assembly - System integrators:

Companies offering complete systems or module development in power electronics

Which forums are dedicated specifically to this topic?

productronica 2025 features four dedicated forums, offering high-profile keynote presentations, inspiring workshops, and valuable discussions – including in-depth sessions on power electronics.

Exhibitors on the Focus Topic of Power Electronics

Renowned exhibitors will present the latest developments, solutions, products, and services in the field of power electronics. Discover which established industry leaders and up-and-coming startups will be attending productronica 2025 in the exhibitor directory, updated daily.